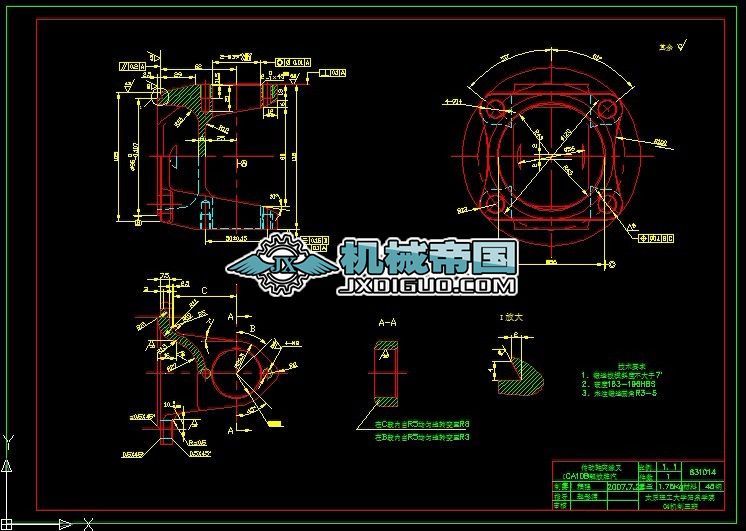

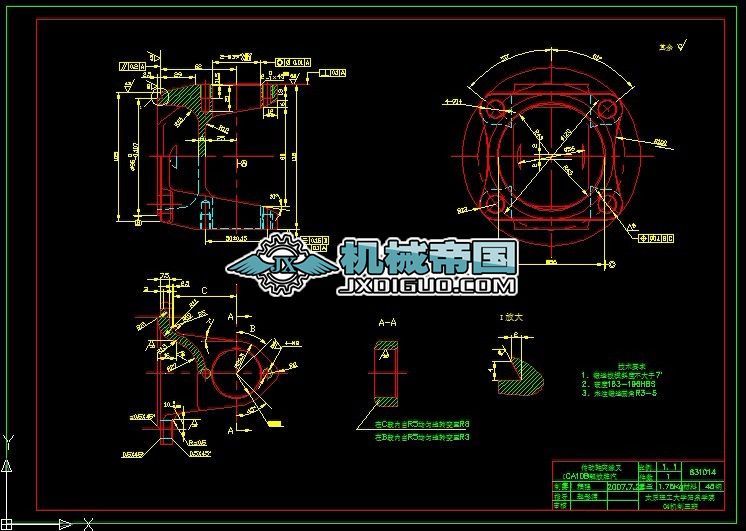

傳動軸突緣叉加工工藝及鉆39孔夾具設計【機械制造課程設計CAD及說明書】

- 文件介紹:

- 該文件為 zip 格式,下載需要 20 積分

-

- 傳動軸突緣叉加工工藝及鉆39孔夾具設計【機械制造課程設計CAD及說明書】

摘要

傳動軸是汽車傳動系統中的重要部件,凸緣叉又是連接變速器和驅動橋的主要零件也是承受高速傳動的零件。其結構和加工工藝直接影響零件的性能,進而影響整車動力傳遞的效果,其結構相對簡單,但是加工工藝復雜。

本文通過搜集資料了解傳動軸凸緣叉結構特點,并對凸緣叉進行了參數分析以及加工的技術要求分析,并通過其在傳動系統中的作用選取適當的材料并確定其工藝流程。 繪制工藝卡片,并查找資料分析相對應的加工機床以及所需要的刀具,明確每一步的加工余量,完成工序的編制過程。在確定工藝過程的前提下,根據傳動軸凸緣叉的結構特點進行對應夾具的設計,根據零件圖及加工端面設計其夾緊機構和定位元件、一起其他輔助零件及聯合整體的零件,確定夾具機構方案,并明確如何拆裝加工工件可以提高總體的效率問題。選取加工粗糙度,設計鉆孔和銑端面的夾具裝置以及鉆孔夾具夾緊力的計算和夾具精度的的校核。

希望制造出精度更高的凸緣叉,使傳動軸更好的運行,提高功率,減少資源浪費,改善工人的勞動條件,降低生產成本以及擴大機床的工藝范圍。

關鍵詞 凸緣叉;工藝流程;加工工藝;夾具設計

Processing Technology and Design of the Jig of the Flange Yoke for Shaft

Abstract

Drive shaft is an important part in automobile transmission system, the flange yoke is connected to the transmission and drive axle of the main parts and it is under high speed driving . The structure and the processing technology impact on the performance of parts directly, in turn, influencing the effect of the vehicle power transmission, its structure is relatively simple, but complicated processing technology.

Based on the collected data to understand the shaft flange fork structure characteristics, and the flange fork parameter analysis and processing technical requirements analysis, and through its role in the transmission system to select the appropriate materials and its technological process were determined. Card drawing process, and find the corresponding machine tool to analyze the data and tools needed to clear every step of the machining allowance, and complete the process of the compilation process. In determining the processes under the premise of according to the structural characteristics of the drive shaft flange fork corresponding fixture design, according to the detail drawing and processing end design of the fastening device and positioning device, other auxiliary parts together and united as a whole parts, jig institutions scheme is determined, and define how to tear open outfit machining can improve the efficiency of the overall problem. Selecting machining roughness, end of the design of drilling and milling fixture device and drilling clamp clamping force calculation and the precision of the check.

That hopes to make the precision higher flange fork, make the shaft running better, improve power and reduce waste of resources, improve the working conditions of workers, reduce production costs and expanding process of machine tool.

Keywords Flange yoke; The process; Processing technology; The design of jig

目錄

摘要 I

Abstract II

第1章 緒論 1

1.1 論文研究背景 1

1.2 論文研究的目的和意義 2

1.3 國內外研究現狀 2

1.4 研究內容 3

第2章 凸緣叉結構分析 5

2.1 凸緣叉的結構特點及功用分析 5

2.2 凸緣叉結構分析 6

2.3 凸緣叉的主要技術要求 7

2.4 凸緣叉的工藝分析 7

2.5 本章小結 9

第3章 傳動軸凸緣叉的加工工藝 10

3.1 概述 10

3.2 確定毛坯的制造形式 10

3.3 基面的選擇 10

3.4 加工工序安排 12

3.5 制定工藝過程 12

3.6 工藝過程方案論證 12

3.7 機械加工余量的確定 14

3.8 保證加工精度的方法 15

3.9 本章小結 17

第4章 凸緣叉夾具設計 18

4.1 論述 18

4.2 夾具設計中應注意的問題 19

4.3 專用夾具設計與原則 21

4.4 夾具設計程序 22

4.5 鉆孔夾具 25

4.6 本章小結 28

結論 29

致謝 30

參考文獻 31

附錄A 32

附錄B 55

...