畢業(yè)設計 煤礦井下運輸水平帶式輸送機設計【圖紙及說明書】

- 文件介紹:

- 該文件為 zip 格式,下載需要 20 積分

-

- 畢業(yè)設計 煤礦井下運輸水平帶式輸送機設計【圖紙及說明書】

摘 要

輸送機械又稱連續(xù)輸送機械,它是沿著一定的輸送路線運輸貨物的機械。在現(xiàn)代化的大企業(yè)中,有大量的原料、半成品和成品(如礦石、焦炭、耐火材料、水泥、化肥、建筑材料、谷物等)需要機械搬運,除了起重機械搬送一部分可以裝箱或堆垛的大件物品外,大量的粒散料和小件物品的運輸,是靠各種形式的運輸機來完成的,在有些工藝流程中,運輸機械還是必不可少的生產(chǎn)機械。

運輸機械的形式很多,本設計為輸送機械的第一類,即固定式帶式輸送機的設計。

帶式輸送機是用連續(xù)運動的無端輸送帶輸送貨物的機械。隨著全球經(jīng)濟的增長,帶式輸送機技術已成為當代科學技術發(fā)展的前沿之一。當今世界需要設計和生產(chǎn)“環(huán)保”型輸送機,要求輸送量超過10000t/h,并且要節(jié)約能量。輸送機技術進步的一個重要特點是基礎研究發(fā)展為應用技術,進而實現(xiàn)商業(yè)化。

帶式輸送機是用途最為廣泛的一種運輸機械。主要應用在沿水平方向或沿坡度不大的傾斜方向,連續(xù)的大批量地運送粒散狀物料或單件物品。它具有生產(chǎn)率高、運送距離長、工作平穩(wěn)、結構簡單、可以在任意位置上裝卸、自重小、工作可靠、操作簡便、耗能少等重要優(yōu)點。

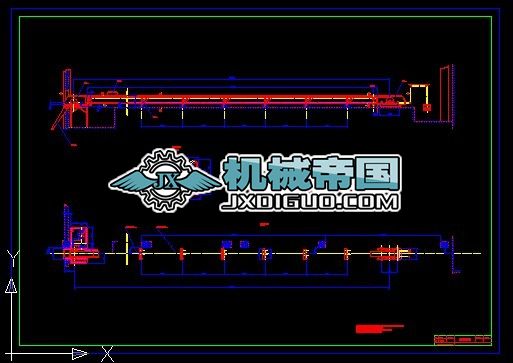

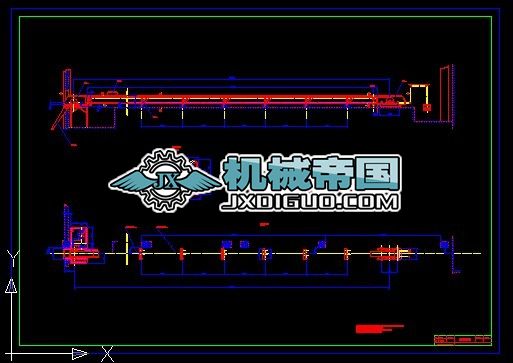

在本文中,詳細地根據(jù)要求對帶式輸送機的全部過程進行了設計和計算,即總體設計計算、各部件的設計選用,并繪制了總裝圖及其主要部件的零件圖。

關鍵詞:輸送機械;固定式;帶式輸送機

Abstract

Transport machine is called the consecution transports machine, it is a machine which conveyances goods along certainly transport route .In modern big business enterprise, there are a great deal of raw material ,seml-processed goods and the finished product(such as the mineral stone,coke,fire-proof material ,cement, turn fatty, construct the material, corn…etc.)demand to be porteraged by machine ,ni addition to the derrick moving to send a part and canning pack or a product of a,the conveyance of a great deal of grain spreads and product ,theconveyance machine is also an essential production machine .

This design is the first Category of the transport machine ,and the design of the fix type take type transports machine.

The take type transports machine is a machine that transports the goods with the fix type take type transports machine .

The take type transports machine is a machine that transports the goods with the without cause belt and continuous sport conveyer .With the development of the world economy ,the technique of the take type conveyance has become one of the fuont of thecontemporary science technique development ,science technique development,desingning an produce the type of “environmental protection” transport machine ,requesting to transport the quantity over 1000ts/h,and to economize the enegy .An important characteristics of the progress of the technique of transports machine is that foundation research development chang into applying the techniqre ,then carry out commercial.

Belt conveyor is one of the most widely used transportmachinery , Mainly used in the oblique direction along the horizontaldirection or along the slope, large batch and continuousdelivery of grain bulk material or single articles. It has the advantages of high efficiency, longtransportation distance, stable work, has the advantages of simple structure, loading and unloading, at any position on small weight, reliable work, convenient operation, low energy consumption and other important advantages.

In this paper, detailed according to the requirement of the whole process of belt conveyor is designed and calculated, the design calculation, such as general designof each component, and draw the assembly drawing and the main parts of the parts diagram. Keywords: conveying machinery; fixed; belt conveyor

目 錄

1 概 述……………………………………………………………………4

1.1 帶式輸送機的發(fā)展應用狀況…………………………………………4

1.2 設計的目的和意義……………………………………………………8

1.3 設計原理及要點………………………………………………………12

1.4 帶式輸送機的布置形式………………………………………………13

2 輸送帶的設計計算 ……………………………………………………15

2.1 已知原始數(shù)據(jù)及工作條件 …………………………………………15

2.2 計算步驟………………………………………………………………15

3 部件的選用 ………………………………………………………┉…24

3.1帶式輸送機應用范圍及選用…………………………………………24

3.2 輸送帶…………………………………………………………………25

3.3 驅動裝置………………………………………………………………27

3.4 電動滾筒………………………………………………………………28

3.5 傳動滾筒………………………………………………………………28

3.6 改向滾筒………………………………………………………………29

3.7 托輥……………………………………………………………………29

3.8 拉緊裝置………………………………………………………………32

3.9 清掃器…………………………………………………………………33

3.10 裝載裝置 ……………………………………………………………34

3.11 卸料裝置 ……………………………………………………………35

3.12 制動及逆止裝置 ……………………………………………………35

3.13 機架 …………………………………………………………………36

3.14 電氣及安全保護裝置 ………………………………………………39

4 輸送機的保護裝置 ……………………………………………………41

4.1 固定式帶式輸送機皮帶跑偏的原因及糾正措施 …………………41

4.2 固定式帶式輸送機的安裝、試運轉和調(diào)整 ………………………44

4.3 固定式帶式輸送機的安全操作、維護和保養(yǎng) ……………………46

總結 ……………………………………………………………………………48

參考文獻………………………………………………………………………49

致謝 ……………………………………………………………………………50

...